- +92-322-4374010

- jahanzaib@manzapparel.com

- 7KM Thoker Naiz Baig Canal Bank Road Lahore Pakistan

Home / Production Process

Layered fabrics are precisely cut using advanced tools to maintain accuracy, reduce waste, and ensure perfect fit.

Layered fabrics are precisely cut using advanced tools to maintain accuracy, reduce waste, and ensure perfect fit.

We apply various washing techniques—including eco-friendly methods—to enhance comfort and performance.

Each garment is carefully finished with trimming, pressing, tagging, and folding for a clean, retail-ready presentation.

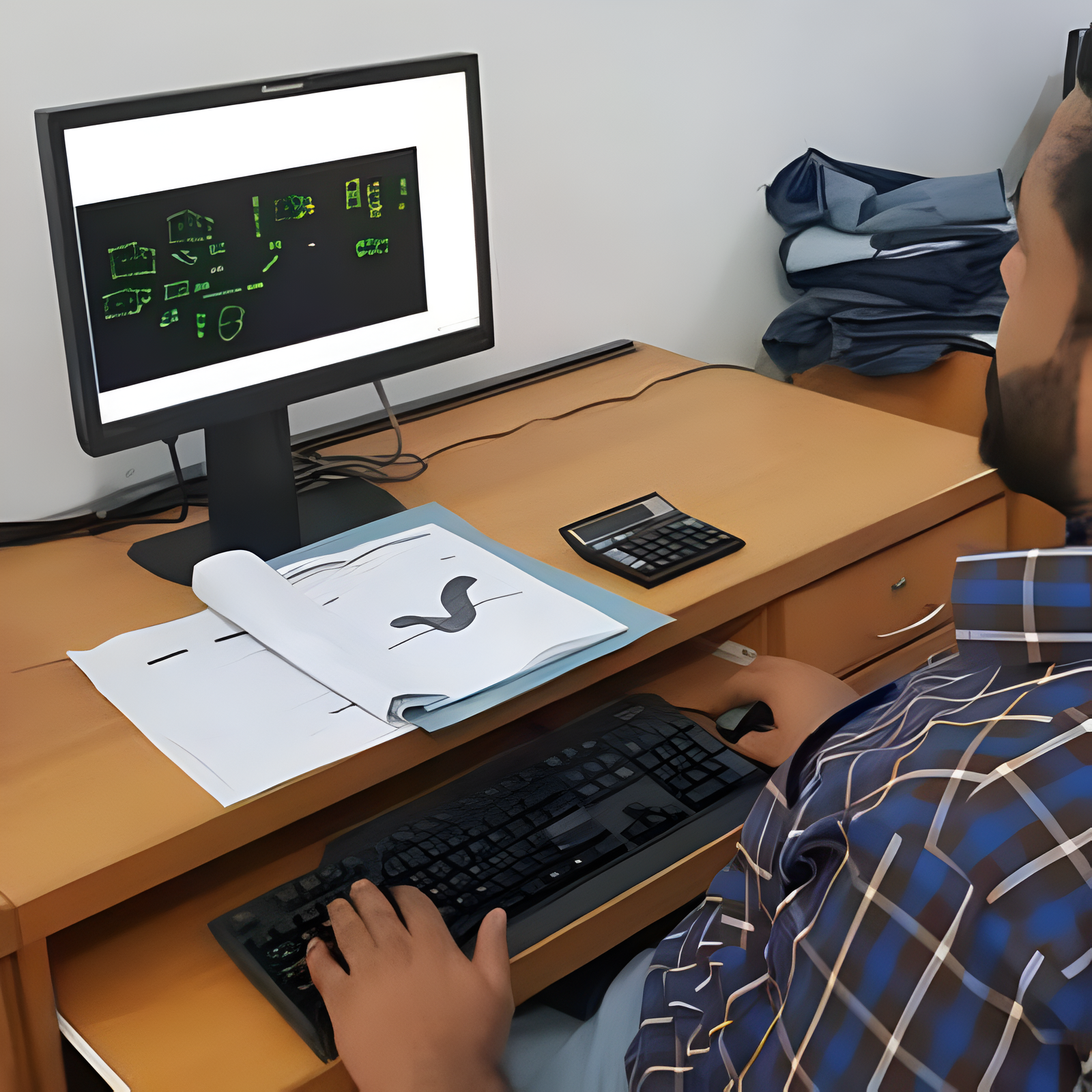

We offer GGT support—pattern making, grading, and marker layout—for precision and efficiency.

From packaging to shipping, we ensure safe handling and timely international delivery with complete tracking support.

At Manz Apparel, the GGT process is the foundation of

our garment manufacturing cycle. It ensures that every

product we create is consistent in fit, structure, and style

regardless of size or design complexity.

Pattern Making: We develop a master pattern using CAD systems and manual techniques based on client designs and measurements.

Grading: The master pattern is scaled into multiple sizes, ensuring consistent fit across all age groups and body types.

Marker Making: A layout is created to place pattern pieces efficiently on fabric, reducing waste and optimizing cutting.

Sampling & Approval: A sample is produced for client approval before bulk production to ensure perfect fit, style, and construction.

The washing process plays a vital role in enhancing the

look, feel, and performance of the garments. At Manz

Apparel, we offer a wide range of industrial washing

techniques tailored to different fabrics, especially

denim, to achieve various textures, finishes, and color

effects

Subscribe to our newsletter for the latest updates on production capabilities, new collections, and industry insights.